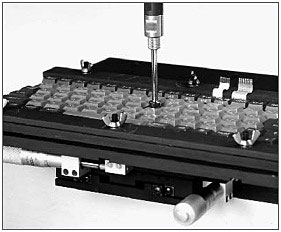

Keyboard Compression Test Jig

Features:

- Uses a 30 mm (1.2 in) compression plate to compress keys on keyboards

- Compatible with 50 N (11 lbf) to 10 kN (2,200 lbf) AG-X plus series and AGS-X series load cells

- Keyboard holder includes micrometers to align keys with the compression plate

- 100 N (22 lbf) maximum capacity

Relevant Materials:

Electronics

This test jig is used for compression testing keys on computer keyboards. The keyboard compression test jig includes a 30 mm (1.2 in) compression plate, a keyboard holder, and a compression and bending loading jig. It should be ordered according to the capacity of the load cell with which it will be used. Compatible load cells are AG-X plus series and AGS-X series load cells with a maximum capacity from 50 N (11 lbf) to 10 kN (2,200 lbf).

The keyboard is clamped into a holder attached to the table of the universal tester. This holder is designed with micrometers to move the keyboard in the x- and y-directions aligning the keys with the compression plate.

This keyboard compression test jig cannot be installed on universal testers with safety covers attached.

News / Events

-

AUTOGRAGH AGS-X2 Series has been released

The Shimadzu AUTOGRAPH AGS-X2 series provides superior performance and practical testing solutions for a wide array of applications. Offering high-level control and intuitive operation, the AGS-X2 series sets a new standard for strength evaluations while providing the utmost in safety considerations in a modern, stylish design.

-

AUTOGRAGH AGS-V Series has been released

Shimadzu Corporation released the Autograph AGS-V Series precision universal testing machine. In this series, the range over which the force measurement accuracy is guaranteed has been increased by a factor of two compared with existing machines. As a result of this new function, the work required to change force measurement sensors and accessories required for measurement can be reduced.

-

High-Speed Video Camera HyperVision HPV-X3 has been released

Recording speed of 20 million frames/second, the highest in its class provides larger, clearer, high-sensitivity recording. HPV-X3 is equipped with a synchronized recording function and high-level analytical capabilities that accommodate a variety of software programs.

-

New Video: AUTOGRAPH AGX-V2 Voice Operation Device XV-Talk

We will introduce how XV-Talk, the world's first voice control device installed in Shimadzu's latest tensile tester AGX-V2, can be used in various scenarios.

-

New Video: AUTOGRAPH AGX-V2 Operation Control Panel Stand-alone test feature

We will introduce a new feature of Shimadzu's latest tensile tester, AGX-V2, a stand-alone testing function using a large color LCD touch panel.

-

New Autograph AGX-V2 Series Precision Universal Testing Machines

The World’s First Testing Machines Equipped with a Voice Operation Device