3-3) Channeling Caused by Bubbles Forming or Accumulating Inside Columns

Problems with Formation of Bubbles in Flow Lines

HPLC systems can experience a range of problems, including air bubbles, peak tailing, peak broadening, and flow instability. One common but often overlooked issue is bubble formation inside the column, which directly affects chromatographic performance. This page explains why bubbles occur, how they cause peak distortion, and what steps can be taken to prevent them.

Channeling Caused by Bubbles Forming or Accumulating Inside Columns

Air entering the mobile phase or column can lead to multiple chromatographic problems such as inconsistent retention, distorted or broadened peaks, pressure fluctuations, or tailing. Proper degassing and careful system setup are essential to prevent these issues.

Bubbles tend not to occur inside columns because the increased pressures increase the saturated solubility for air. However, bubbles can tend to form in the relatively low-pressure area near the column outlet if heated by an oven.

It is also possible for air bubbles to accumulate in such area after passing through the pump.

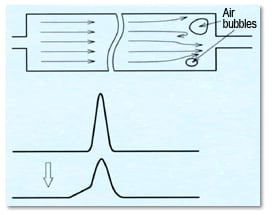

Such cases can cause the flow of mobile phase in the column to vary, resulting in peak distortion (Figure 13).

Fig. 13Channeling Due to Bubbles Inside the Column

Note that the larger the column diameter, the more difficult it is for bubbles to pass out of the column.

Therefore, if a preparative column is attached to the HPLC system, install the column so the inlet is as high as possible and the outlet as low as possible to minimize the bubbles having to overcome buoyancy.

How Bubble Formation Leads to Peak Tailing and Peak Broadening

When bubbles disrupt the flow path, analytes experience inconsistent interaction with the stationary phase. This commonly appears as peak tailing, broad peaks, reduced efficiency, or erratic retention times.

How to Prevent Bubble-Related HPLC Problems

- Ensure mobile phase is fully degassed

- Avoid low-pressure zones near heated outlets

- Confirm pump seals and inlet lines are airtight

- Install preparative columns with inlet high / outlet low (as described above)

- Maintain stable oven temperature

FAQ

How do bubbles form inside an HPLC column?

Bubbles typically form in low-pressure regions near the column outlet or when the column is heated. Air can also enter through pump seals or mobile phases that are not fully degassed. These bubbles disrupt flow and lead to channeling and peak distortion.

What is the best way to prevent bubble-related HPLC problems?

Ensure thorough mobile-phase degassing, maintain airtight solvent lines, avoid temperature gradients, and mount preparative columns with the inlet positioned higher than the outlet. These steps minimise bubble accumulation and improve flow consistency.

What troubleshooting steps should I take if I suspect bubble formation?

Purge the system, re-degass solvents, check pump inlet lines for leaks, stabilise the oven temperature, and inspect fittings around the column outlet. Reinstall the column properly to avoid low-pressure, heated zones where bubbles tend to form.