Features

- Mounted directly under a vessel, SBJV and SBJLV gear pumps have a special wide-mouth suction port to ensure the extraction of high viscosity polymer of approximately 20,000 Pa·s (0.250 bar). (Ex. polystyrene)

- Immediately after activation, SBJV gear pumps can pressurize extracted polymer from a vacuum reactor up to a maximum of 25 MPaG (250 bar).

- Shimadzu's proprietary pressure adjustment mechanism on the shaft seal prevents air from being drawn through the shaft seal into the vacuum chamber.

- Four types of gear pump shaft seals are available to suit a wide variety of liquid characteristics and operating parameters.

Shaft Seal Types - SBJ series gear pumps are jacketed to allow heating or cooling to suitable temperatures.

- SBJ series pumps are available in 4 model types to meet a variety of applications, in capacities ranging from 45 cm3/rev to 25000 cm3/rev. Easily find a pump that satisfies your requirements.

Applications

- Synthetic fibers: Polyester, nylon, polypropylene and others

- Plastics: Polyester, polystyrene, ABS resin, AS resin, HDPE, LLDPE, PBT, phenol resin, polyvinyl chloride and others

- Films/Sheets: Polyester, polystyrene, polypropylene, polycarbonate and others

SBJV type : For Polymer discharge

SBJV gear pumps are installed under a reactor to discharge various types of polymers such as PET and PS. These high-pressure pumps raise pressure from a vacuum to 25 MPaG (250 bar) in a single step. Large diameter suction port is perfect for extracting high-viscosity polymers.

SBJLV type : For Prepolymers

Compact pump provides maximum 7 MPaG (70 bar) discharge pressure, making it suitable for prepolymers. Attached directly to bottom of vacuum chamber, this pump's large-diameter port allows pumping of even high-viscosity liquids.

SBJL type : For Solutions and Oilgomers

Compact design provides maximum 7 MPaG (70 bar) discharge pressure and is ideal for solutions, oligomers and other low-viscosity liquids. Can be mounted inline either vertically or horizontally.

SBJ-LL type : Booster Pumps

Delivers reliable feed under high suction pressures. This gear pump is designed as a booster pump for environments with suction pressures of over 1 MPaG.

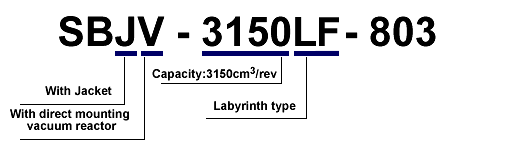

Pump Model

Example: SBJV3150LF-803

| LF | : | Shaft Seal (GP: Gland Packing Seal, LF: Labyrinth Seal (Female), LM: Labyrinth Seal (Male), M: Double Mechanical Seal) |

| 8 | : | With pressure-adjustment mechanism for pressurizing shaft seal |

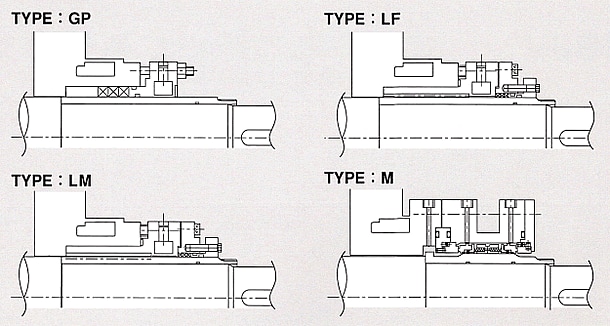

Four Types of Shaft Seals

These gear pumps are equipped with the following types of shaft seals to suit a wide variety of applications.

| GP | Gland Packing + Neck Bushing + Cooling Gland packing (molded fiber gasket) and neck bushing are combined with polymer cooling to seal the pump. Often used for polymers with low viscosity. |

|---|---|

| LF | Labyrinth Seal (female threads) + Cooling + Gland Packing (for supplemental sealing or cleaning) Labyrinth seals include a gap that fills with polymer, which increases in viscosity when cooled to make a seal. This provides a more effective seal, does not contact the shaft, has excellent durability, and is maintenance free. |

| LM | Labyrinth Seal (male threads) + Cooling + Gland Packing (for supplemental sealing) Type LF seals have spiral threads on the inside of the labyrinth, while the LM seal has these threads on the outside, and can be chosen according to liquid characteristics and pressures. |

| M | Double Mechanical Seal This mechanical seal consists of sealing liquid enclosed between two sheets with friction surfaces made of wear-resistant material that completely separates the polymer from the atmosphere. This seal is used as a safety measure with polymers containing flammable substances such as hexane. |

Pressure Adjustment Mechanism

To prevent air from entering the shaft seal, a portion of the polymer from the discharge side is sent via the valve to the shaft seal to provide a fixed pressure in the shaft seal. A channel in the pump body returns the polymer to the suction port. For more information, contact your nearest Shimadzu sales representative.

Shaft Seal Comparison Table

| TYPE | GP | LF | LM | M | ||

|---|---|---|---|---|---|---|

|

|

|

|

|

|||

| Construction of Seal | Gland packing +Bush +Cooling |

Labyrinth (inside groove) +cooling +Gland packing (assist) |

Labyrinth (outside groove) +cooling +Gland packing (assist) |

Double Mechanical | ||

| Utility | Air (300NL/min) or Water (1 to 3L/min) |

Air (300NL/min) or Water (1 to 3L/min) |

Air (300NL/min) or Water (1 to 3L/min) |

Seal Oil And Pressurising Unit |

||

| Applicable Suc. Pressure | Full Vacuum to 3MPaG | Full Vacuum to 15MPaG | ‹ATM | Full Vacuum to 15 MPaG | Full Vacuum to 1 MPaG(Unbalance type) | |

| Applicable Dis. Pressure | Not specially required | Not specially required | Min. 10 MPaG | Not specially required | Not specially required | |

| Viscosity | Melting Point Yes | Min. 10mPa·s | Min. 10mPa·s | - | - | |

| Melting Point No | Min. 0.1Pa·s | Min. 30Pa·s | Min. 30Pa·s | - | ||

| Special Conditions At Seal Selection |

1.Pump should not be operated when polymer is not yet reacted at start-up. 2.Life time gland packing is normally 1 year. |

1.Specially effective for PET. 2.Full vacuum suc. Pressure is applicable. 3.PS pre-polymer stage is applicable to used gland packing together. |

1.Specially effective for PS/SAN booster pump. 2.If less than 10MPaG. Dis.Pressure and full vacuum Suc. Pressure should not be applied. |

1Mechanical seal should be applied for SAN solution as leakage is not permitted. 2.High price, complicated construction. 3.Mech. seal assembly must be replaced at leakage as costly. |

||

| Service | PET | Oligomer Pre-polymer Polymer |

Oligomer Pre-polymer Polymer Booster |

- | - | |

| PS/SAN | Solution Pre-polymer Polymer |

Pre-polymer Polymer |

Polymer Booster |

Solution Pre-polymer Polymer |

||