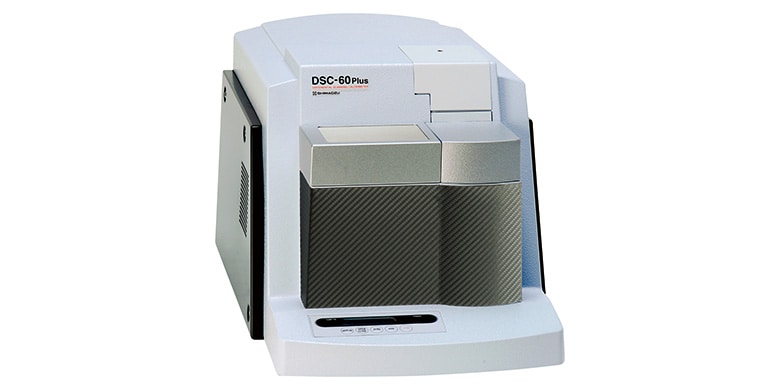

DSC-60 Plus Series

- Changes in physical properties due to heat treatment can be evaluated by using a tensile testing machine and hardness tester. - Multifaceted evaluation by thermal analysis, FTIR, and other techniques is effective for study of the cause of changes in physical properties. - Data from tensile tests and hardness tests can be accumulated and is a useful tool for quality control. - In hardness testing, hardness can be evaluated simply by applying a load to a partial area of the specimen, making it possible to evaluate hardness with the actual shape of the part.

As a plant-derived plastic material, polylactic acid resin (PLA) is expected to reduce environmental loads, including global warming and depletion of petroleum resources. Although PLA was originally developed as an alternative to acrylonitrile- styrene-butadiene resin (ABS), which is widely used in automobiles and electrical products, its durability and heat resistance are inferior to those of ABS, and high temperature crystallization treatment (annealing treatment) is necessary to achieve comparable performance. However, an accurate understanding of the material properties resulting from annealing treatment is essential for obtaining the targeted properties in PLA. In this article, the difference in material properties due to annealing treatment was evaluated by tensile testing and hardness testing, and the state of crystallization in the respective specimens was then evaluated by differential scanning calorimetry (DSC) and Fourier transform infrared spectrophotometry (FTIR). Annealing was carried out at 100 ̊C for 30 minutes.

September 29, 2022 GMT

Some products may be updated to newer models