i-Series - Features

High Performance Liquid Chromatograph

intelligent

The new i-Series models offer three key functionalities for diagnosis, prevention, and system restoration to maintain analytical robustness.

Diagnoses Pump and Autosampler Status

During the pump’s flow path check, the system identifies check valve malfunctions, while the autosampler’s flow path check detects contamination and blockages in the injection system.

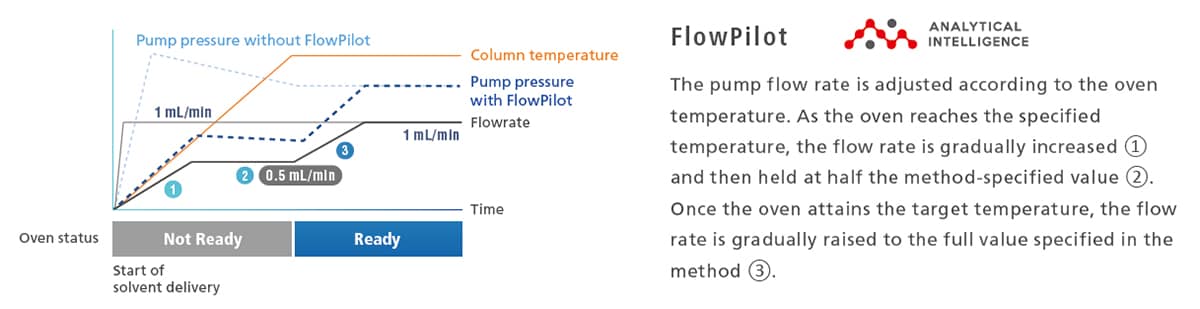

Automatic Equilibration with Column Protection

To prevent column deterioration caused by sudden pressure spikes, the mobile phase flow rate should be gradually increased as the column temperature rises. The FlowPilot flow rate control feature is synchronized with the column oven temperature, ensuring columns are protected from abrupt pressure changes during automatic equilibration.

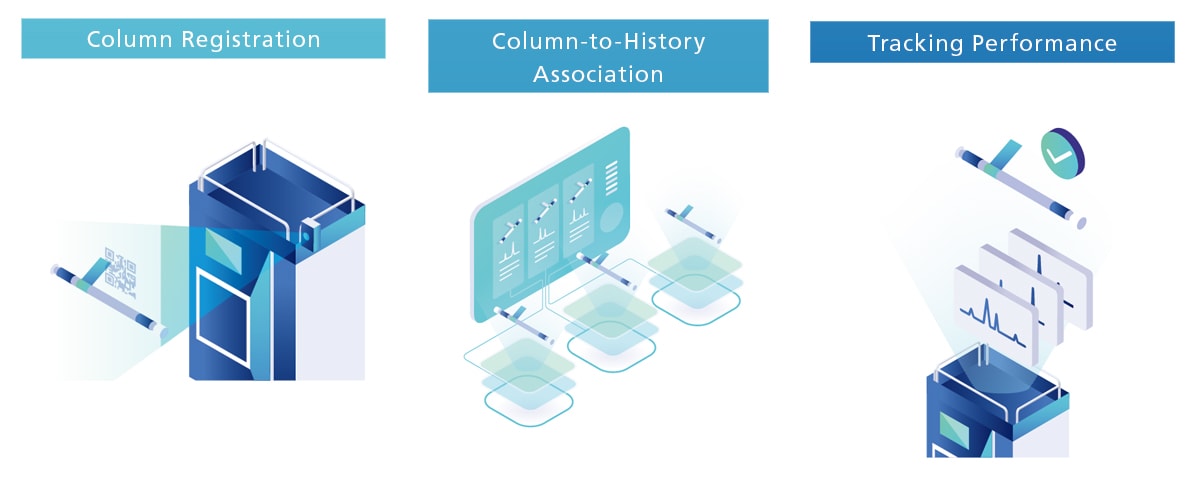

iCMP Next-Generation Column Management

Maintaining a record of column usage history is crucial for ensuring high data reliability. The intelligent Column Management Platform (iCMP)* provides an integrated solution for tracking column usage,

improving both usability and data integrity.

* Sold separately. Only available with LabSolutions CS.

innovative

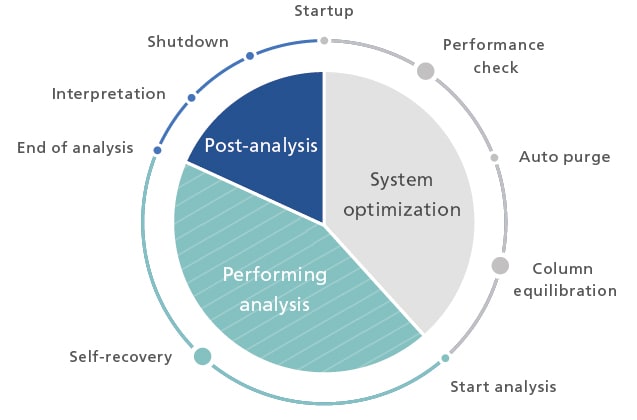

Enhancing Workflows Through Automation and Remote Monitoring

With FlowPilot automated flow rate control, mobile phase monitoring, Analytical Intelligence driven functionality, and LabSolutions Direct software, everything from system startup to analysis shutdown can be managed through automated processes or remote control/monitoring. These automated workflows embed the expertise of seasoned analysts, ensuring consistent data acquisition over extended periods while reducing manual labor in the lab and enhancing overall productivity.

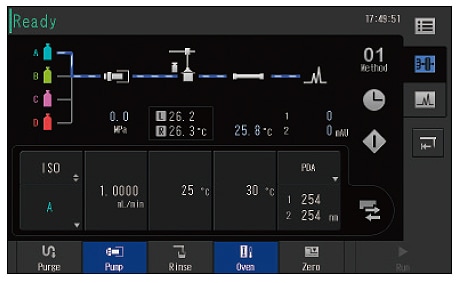

intuitive

The intuitive user interface mirrors the system’s flow path, allowing users to easily visualize operating status. Methods can be created or edited directly from the same screen, streamlining operation. Designed for ease of use, the interface enables even first-time liquid chromatography users to get started with minimal training.

The auto-validation function allows any user to follow a standardized procedure to easily verify instrument condition. It automatically checks key performance metrics, such as solvent delivery stability, wavelength and absorbance accuracy, gradient precision, and signal drift or noise. In addition, a built-in instrument check function performs routine pre-run inspections and generates a comprehensive report with self-diagnostic results and consumables usage—tracking solvent volume delivered, total injections by the autosampler, and lamp operating hours. All auto-validation results are centrally managed, enabling quick and accurate assessment of instrument status.