Flexural Test Methods for Plastics: ISO 178 and JIS K 7171

Resin materials (plastics) are found in a wide variety of items used on a daily basis. Recently, plastics have started to be used as structural materials in transportation equipment, such as automobiles and aircraft, due to their strength and light-weight nature. In these applications, it is important to understand the mechanical strength properties of these plastics.

Testing the flexural properties (bending properties) of plastics and other resin materials are covered in ISO 178 and JIS K 7171. These methods include calculations for the mechanical properties and accuracy specifications for the measuring systems used.

The ASTM standard for flexural testing of plastics, ASTM D790, has slightly different requirements compared with ISO 178 and JIS K7171, which are essentially the same. For more information about ASTM D790, please click here.

Features

-

A test force accuracy that meets ISO 7500-1 Class 1 and JIS B 7721 Class 1, accuracy within ±1% of the indicated...

-

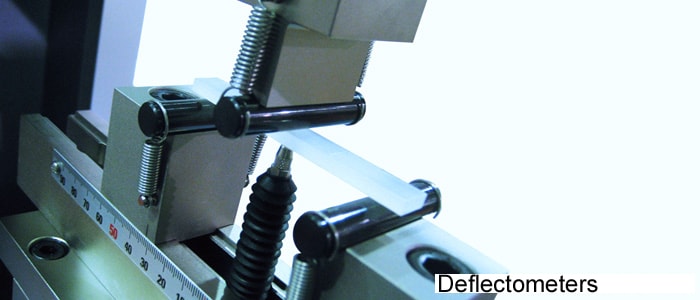

ISO 178 and JIS K 7171 require ISO 9513 Class 1 accuracy (accuracy within 1% of the indicated value) for...

-

ncluded in the annexes of ISO 178 and JIS K 7171 are crosshead displacement and compliance correction...

-

The radius of the punch and supports of the 3-point bend test fixture used for ISO 178 and JIS K 7171 flexural test...

News / Events

-

AUTOGRAGH AGS-X2 Series has been released

The Shimadzu AUTOGRAPH AGS-X2 series provides superior performance and practical testing solutions for a wide array of applications. Offering high-level control and intuitive operation, the AGS-X2 series sets a new standard for strength evaluations while providing the utmost in safety considerations in a modern, stylish design.

-

AUTOGRAGH AGS-V Series has been released

Shimadzu Corporation released the Autograph AGS-V Series precision universal testing machine. In this series, the range over which the force measurement accuracy is guaranteed has been increased by a factor of two compared with existing machines. As a result of this new function, the work required to change force measurement sensors and accessories required for measurement can be reduced.

-

High-Speed Video Camera HyperVision HPV-X3 has been released

Recording speed of 20 million frames/second, the highest in its class provides larger, clearer, high-sensitivity recording. HPV-X3 is equipped with a synchronized recording function and high-level analytical capabilities that accommodate a variety of software programs.

-

New Video: AUTOGRAPH AGX-V2 Voice Operation Device XV-Talk

We will introduce how XV-Talk, the world's first voice control device installed in Shimadzu's latest tensile tester AGX-V2, can be used in various scenarios.

-

New Video: AUTOGRAPH AGX-V2 Operation Control Panel Stand-alone test feature

We will introduce a new feature of Shimadzu's latest tensile tester, AGX-V2, a stand-alone testing function using a large color LCD touch panel.

-

New Autograph AGX-V2 Series Precision Universal Testing Machines

The World’s First Testing Machines Equipped with a Voice Operation Device