Electronic Components

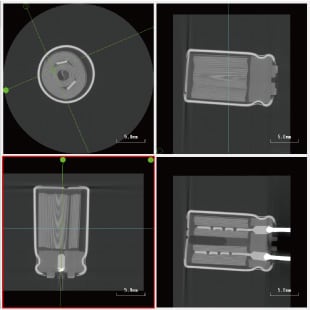

Microfocus X-Ray Inspection System

Adding the detachable rotation/ inclination unit enables X- ray fluoroscopy of small parts from a number of directions, reducing omissions in inspections.

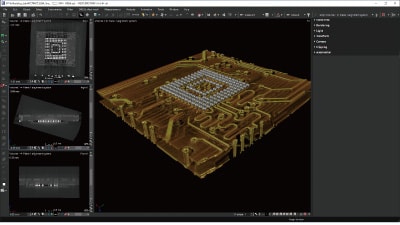

This software uses volume rendering (VR) to di splay three-dimensional images from cross-sectional images obtained using X-ray CT imaging. It includes functionality for creating basic animation and simple measurements.