Vacuum Heat Treatment Technology

Aimed at Lighter Weight, Higher Capacity, and Increased Mass Production of Automotive Parts

We offer a rich lineup of small to large vacuum furnaces to meet the needs of various non-oxide ceramics sintering applications and improve maintainability for mass production.

Features

【Unique Structure】

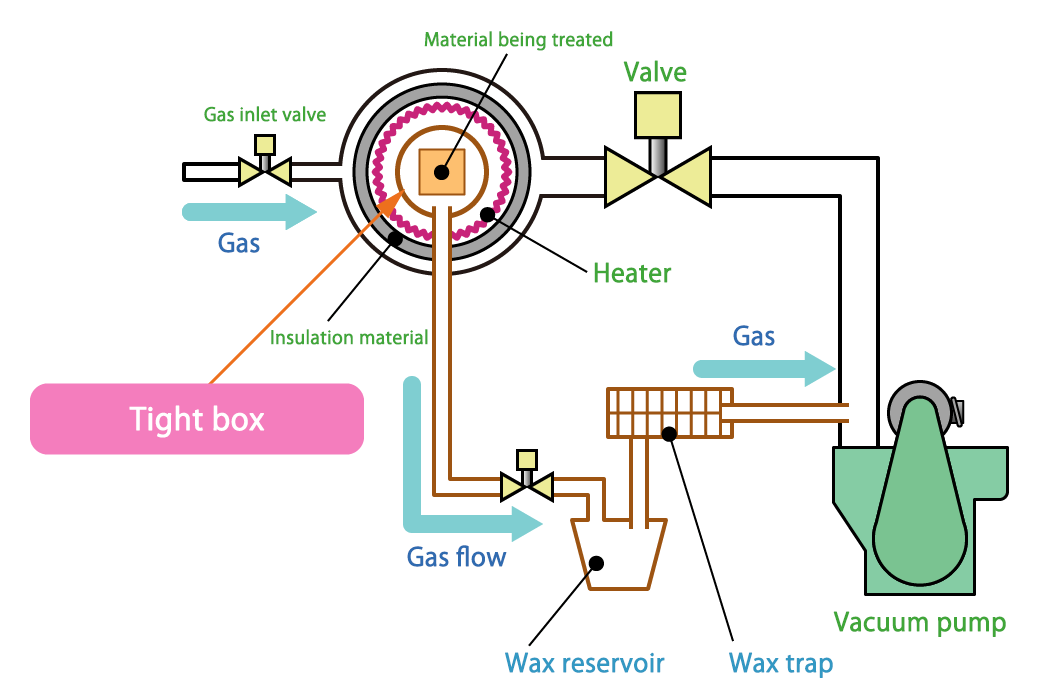

An inner case (tight box) is installed between the heater and the material being treated to minimize contamination of the furnace by gases and binders generated from the material.

A tight box is installed between the processed material and the heater/insulation material, and gas is introduced from outside the tight box and drawn from inside the tight box by a vacuum pump to prevent gas, wax, etc. generated from the material being treated from adhering to the heater and insulation material.

User interface

Easy to operate and understand

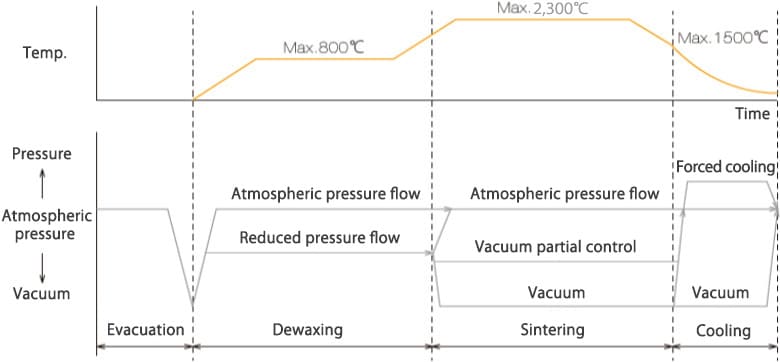

Basic heat treatment pattern

Pressure-Vacuum Dewaxing-Sintering Furnace

PHS Series