Hyper Vision HPV-X2

High-Speed Video Camera

Medical science and engineering have made dramatic progress thanks to visualization technology. Examples include the invention of microscopes capable of enlarged observations of phenomena occurring in the microscopic domain, invisible to the human eye, X-ray inspection systems, which enable the observation of images utilizing light at imperceptible wavelengths, and infrared cameras. Our eyes are incapable of capturing phenomena occurring at times shorter than 50 to 100 ms. As a result, high-speed video cameras have become necessary in order to record phenomena occurring at intervals that cannot be seen with the human eye, and then replay them at a slower rate so that they can be visualized. As the standard tool for visualizing ultra high-speed domains, the Hyper Vision high-speed video camera contributes to our understanding of ultra high-speed phenomena in a variety of fields.

|

The high-speed video camera from Shimadzu Corporation celebrated its 20th anniversary in 2025. |

Features

-

Larger, clearer, high-sensitivity recording equipped with synchronized recording function and high-level analytical capabilities that accommodate a variety of software programs

-

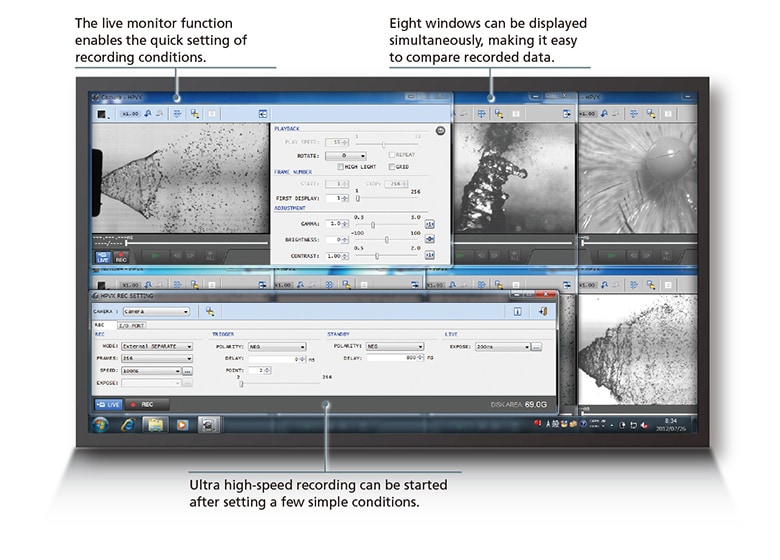

Windows compatible control software is provided. Just connect the camera and PC using a LAN cable and configure the simple settings to start recording at high speeds immediately.

In addition to a special format, the recorded images can be saved in common formats such as AVI, BMP, JPEG, and TIFF. -

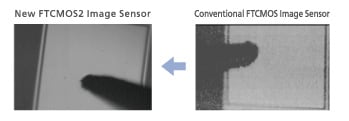

The light sensitivity of the HPV-X2 has been improved six-fold compared to our conventional products by adopting the FTCMOS2 image sensor. The resulting improvement in signal-to-noise ratio yields clearer images compared to conventional products, if the optical systems are the same.

Videos

-

Laser Ablation Film Forming Apparatus

-

The Destruction Process of Microbubbles in Proximity to Cancer Cells Using Ultrasonic Waves

-

High Speed Contraction of Microbubbles

-

Inkjet Printers

-

CFRP Lightning Strike Test

-

High Speed Collision of a Transparent Laminate with a Resin Sphere

-

Supersonic Wind Tunnel Test

-

Dielectric breakdown of the semiconductor device

-

Atomization Process of Fuels Near the nozzle outlet

-

Spark Plugs

-

Atomization Process of Fuels 1 mm from the nozzle

-

Fuel Injection Nozzle Injector for an Automobile Engine

-

Atomization Process of Fuels 2 mm from the nozzle

-

Instantaneous Flash Lighting (Recording speed: 10 million frames/second)

-

Breaking Glass - (Recording Speed 10Mfps)

-

MEMS High-Speed Operation (Recording speed: 10 million frames/second)

-

CFRP High-Speed Tensile Test (Recording speed: 10 million frames/second)

-

Crack Propagation (Glass) (Recording speed: 10 million frames/second)

-

Water Spray (Recording speed: 10 million frames/second)

-

Collision of High Speed Projectiles

-

High Speed Collision of Resin Sphere2

-

Ink Jet Discharge

-

High Speed Collision of Resin Sphere1

-

Milkcrown High-Speed Video Camera

-

Destruction progress of the LED by the overcurrent

-

Propagation of detonation

-

High Speed Tensile Test of Carbon Fiber Reinforced Plastics CFRP

The video illustrates the breakage of the CFRP by the high-speed tensile testing machine. The CFRP fractures instantaneously at the limit load, so a recording speed of 10 million frames/second is required to capture the fracturing process in detail.

-

The world through the lens of a high-speed video camera

In this video we take a look at what a surprise birthday party looks like in slow motion using Shimadzu's high-speed camera. Some scenes are filmed at speeds of even 500,000 FPS!

News / Events

-

AUTOGRAGH AGS-X2 Series has been released

The Shimadzu AUTOGRAPH AGS-X2 series provides superior performance and practical testing solutions for a wide array of applications. Offering high-level control and intuitive operation, the AGS-X2 series sets a new standard for strength evaluations while providing the utmost in safety considerations in a modern, stylish design.

-

AUTOGRAGH AGS-V Series has been released

Shimadzu Corporation released the Autograph AGS-V Series precision universal testing machine. In this series, the range over which the force measurement accuracy is guaranteed has been increased by a factor of two compared with existing machines. As a result of this new function, the work required to change force measurement sensors and accessories required for measurement can be reduced.

-

High-Speed Video Camera HyperVision HPV-X3 has been released

Recording speed of 20 million frames/second, the highest in its class provides larger, clearer, high-sensitivity recording. HPV-X3 is equipped with a synchronized recording function and high-level analytical capabilities that accommodate a variety of software programs.

-

A new video has been released -The world through the lens of a high-speed video camera-

In this video we take a look at what a surprise birthday party looks like in slow motion using Shimadzu's high-speed camera. Some scenes are filmed at speeds of even 500,000 FPS!

-

New Video: AUTOGRAPH AGX-V2 Voice Operation Device XV-Talk

We will introduce how XV-Talk, the world's first voice control device installed in Shimadzu's latest tensile tester AGX-V2, can be used in various scenarios.

-

New Video: AUTOGRAPH AGX-V2 Operation Control Panel Stand-alone test feature

We will introduce a new feature of Shimadzu's latest tensile tester, AGX-V2, a stand-alone testing function using a large color LCD touch panel.