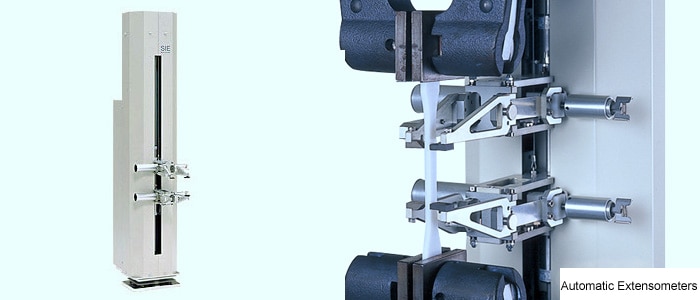

SIE-560A/560SA

Automatic Extensometer

To determine the suitability of a material for an application where it is under load, measuring its elongation is important. Measuring elongation enables determination of the elastic modulus (reversible elongation in the elastic region) by measuring the small initial elongation range, and determination of elongation at specimen failure, by measuring larger irreversible elongation in the plastic region. Shimadzu’s SIE-560A series automatic extensometers accomplish both of these measurements with high accuracy, and provide automated functions that increase testing efficiency and test reproducibility. Ideal for testing a wide variety of materials, including metallic materials, plastics, and composites, the SIE-560A series complies with ISO 527, JIS K 7161, and ASTM D638 standards for plastics tensile testing. In addition, the SIE-560A series supports strain-rate controlled metallic material tensile testing measurements specified in ISO 6892, JIS Z 2241, and ASTM E4

Features Compliant with Plastic and Metallic Material Testing Standards

Features

-

Functions of the SIE-560A series, including the automatic detection of the mid-point between upper and lower grips, the automatic return to a specified gauge position, and the automatic release of specimens after testing is finished, ensure that routine testing can be performed conveniently and reproducibly.

-

The SIE-560A series high-precision measurements are the result of a high-precision magnetic induction linear sensor, an ultra-high precision strain gauge sensor (on SIE-560SA models only), and a newly developed digital strain engine.

News / Events

-

AUTOGRAGH AGS-X2 Series has been released

The Shimadzu AUTOGRAPH AGS-X2 series provides superior performance and practical testing solutions for a wide array of applications. Offering high-level control and intuitive operation, the AGS-X2 series sets a new standard for strength evaluations while providing the utmost in safety considerations in a modern, stylish design.

-

AUTOGRAGH AGS-V Series has been released

Shimadzu Corporation released the Autograph AGS-V Series precision universal testing machine. In this series, the range over which the force measurement accuracy is guaranteed has been increased by a factor of two compared with existing machines. As a result of this new function, the work required to change force measurement sensors and accessories required for measurement can be reduced.

-

High-Speed Video Camera HyperVision HPV-X3 has been released

Recording speed of 20 million frames/second, the highest in its class provides larger, clearer, high-sensitivity recording. HPV-X3 is equipped with a synchronized recording function and high-level analytical capabilities that accommodate a variety of software programs.

-

New Video: AUTOGRAPH AGX-V2 Voice Operation Device XV-Talk

We will introduce how XV-Talk, the world's first voice control device installed in Shimadzu's latest tensile tester AGX-V2, can be used in various scenarios.

-

New Video: AUTOGRAPH AGX-V2 Operation Control Panel Stand-alone test feature

We will introduce a new feature of Shimadzu's latest tensile tester, AGX-V2, a stand-alone testing function using a large color LCD touch panel.

-

New Autograph AGX-V2 Series Precision Universal Testing Machines

The World’s First Testing Machines Equipped with a Voice Operation Device