Xctal 5000 - Applications

Phase-Contrast X-Ray CT System

Most of the documents on the LITERATURE is available in PDF format. You will need Adobe Acrobat Reader to open and read PDF documents. If you do not already have Acrobat Reader, you can download it free at the Adobe's Website. Click the GET ADOBE READER icon on the left to download a free copy of Adobe Acrobat Reader.

Applications (Absorption, Dark-field, and Phase Images)

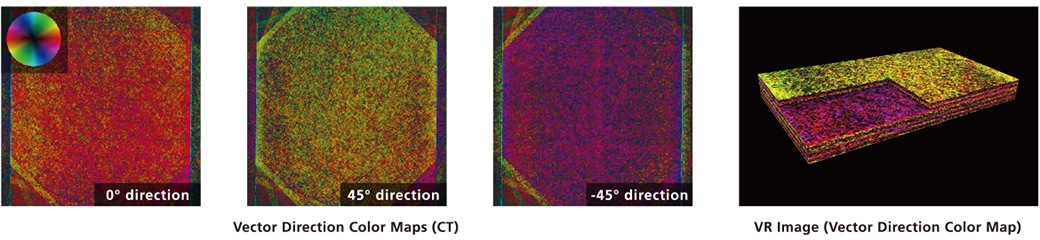

CFRP Laminate Layers

This is a sample scan of a material in which the angle of a prepreg of fibers aligned along one direction is changed to build up the laminate layers. It is evident from the cross-sectional images that there are three orientation directions, and from the VR image, these have evidently been used by turns in the laminate.

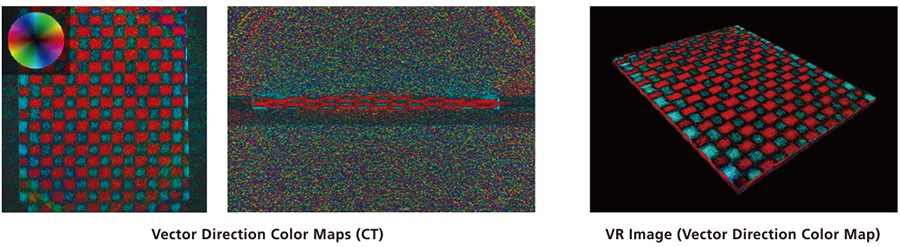

CFRP Cloth Material

This is an example of the analysis of fiber orientations in a laminate material, woven with carbon fibers.

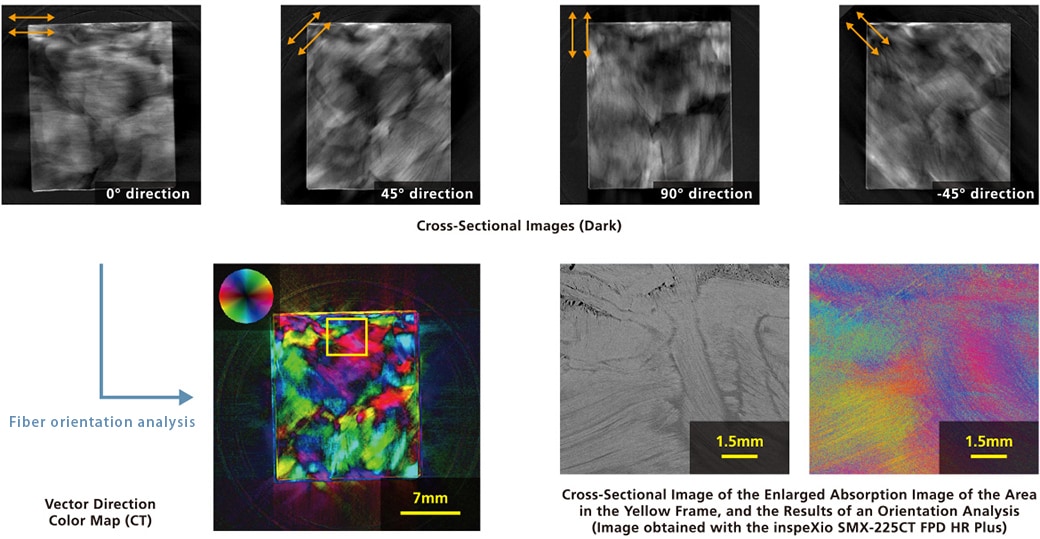

CFRP Random Laminate

This is a sample scan of a material in which pieces of carbon tape with random orientations are used to build up the laminate layers. X-rays scattered along the orientation of the grating are detected, enabling the fibers oriented along these directions to be detected.

With the random sheet of chopped tape, variation of the fiber orientation changes the mechanical properties and moldability, thereby changing the quality of the molded product. The fiber orientation analysis makes it possible to predict the quality nondestructively, and further, enables research into the design of laminates with a slight variation and stable quality.

(Samples and comments provided by: ICC, Kanazawa Institute of Technology)

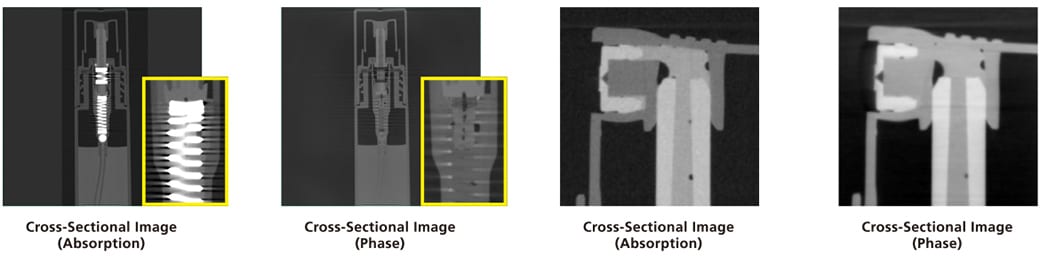

Plastic Bottles

This is a sample scan of a plastic spray bottle. With a phase image, it is possible to observe the voids in the plastic, without the impact of artifacts due to a spring. In addition, the internal structure of the sample where different types of plastic are joined can be observed using absorption and phase images due to the difference in the absorption coefficients and densities.

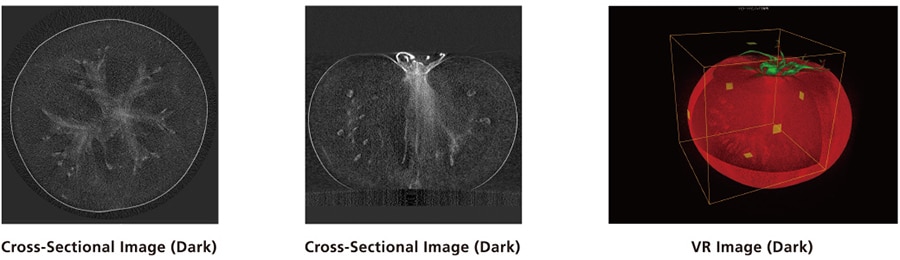

Tomatoes

This is a sample scan of a tomato. The internal structure of the vegetable can be observed even if there is a high moisture content.

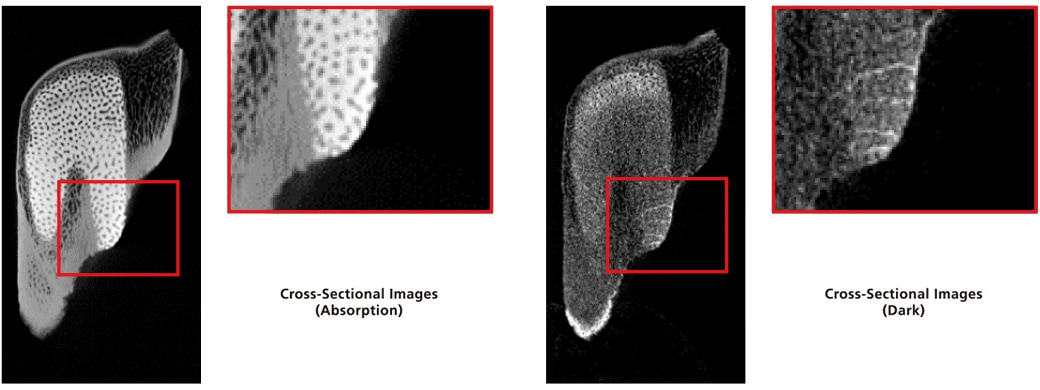

Upper Jaw Tooth Plate of an Elephant Shark

This is a sample scan of an upper jaw tooth plate of an elephant shark.

A number of cracks, probably caused by occlusion, are visualized in the red squared area in the dark-field image (right) of the upper jaw tooth plate of the elephant shark. Whereas cracks are not visible in the absorption image (left). Technique to detect such an internal structural defects nondestructively should be highly useful in development of biomaterial which is subjected to mechanical stress.

(Samples and comments provided by: Dr. Mayumi Iijima, Graduate School of Agricultural and Life Sciences/Faculty of Agriculture, The University of Tokyo)

The affiliation of the providers of the samples and comments is as of July 27, 2022.