inspeXio™ 7000

Microfocus X-Ray CT System

The inspeXio 7000 is a high-performance microfocus X-ray CT system equipped with a Shimadzu microfocus X-ray generator and a large high-resolution flat panel detector.

The large detection area, input resolution equivalent to 14 megapixels, and an enhanced high-output microfocus X-ray generator enable CT images with a large field-of-view, high resolution, and high contrast. In addition, the improved HPCinspeXio high-performance computing system processes images faster.

These developments make the inspeXio 7000 system applicable for researching, developing, or inspecting a wide variety of samples, from composite materials, such as glass fiber reinforced plastic (GFRP) and continuous fiber reinforced thermoplastic laminate (CFRTP) materials to large aluminum die cast parts.

The Analytical Intelligence logo and CORE Boost are trademarks of Shimadzu Corporation or its affiliated companies in Japan and/or other countries.

VGSTUDIO MAX and VGSTUDIO are trademarks of Volume Graphics GmbH.

POLYGONALmeister is a trademark of UEL Corporation.

System Configuration and Operating Principle

-

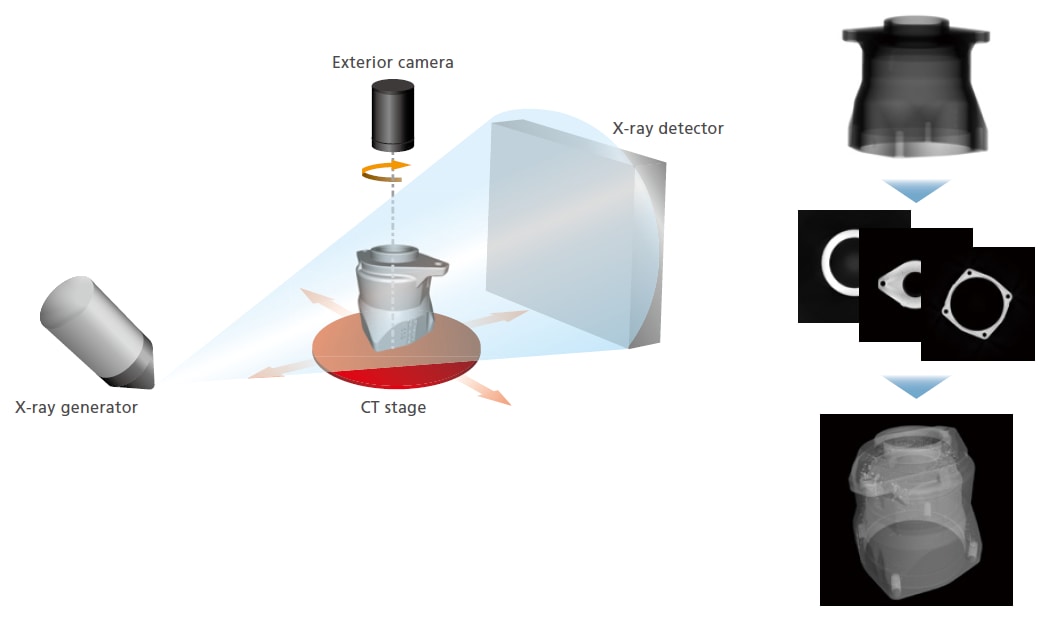

The inspection target (sample) is placed between the X-ray generator and detector, as shown below. Then, the sample is rotated 360 degrees to collect X-ray fluoroscopic data from various angles in order to calculate cross-sectional images.

-

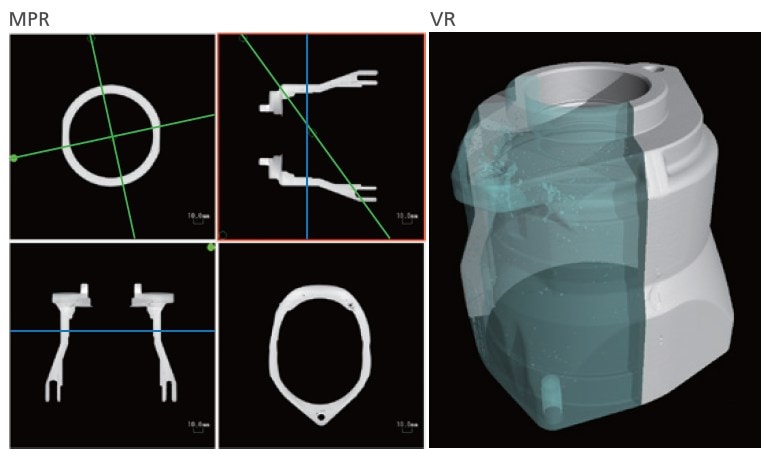

MPR Display

Displays any cross section desired

Multi Planar Reconstruction (MPR) stacks multiple CT images in a virtual space to display four images—a CT image, mutually longitudinal section images, and a user-selected section image orthogonal to one of the longitudinal section images.VR Display

Volume rendering (VR) stacks multiple CT images in a virtual space to display a 3D image. Separate 3D image processing software is required for VR display.

Features

-

The large high-resolution flat panel detector has an input resolution equivalent to 14 megapixels, which provides a large field-of-view and high resolution.

-

Improvements to the Shimadzu-made microfocus X-ray generator and the sensitivity characteristics of the state-of-the-art flat panel detector enable unprecedented high output and image contrast.

-

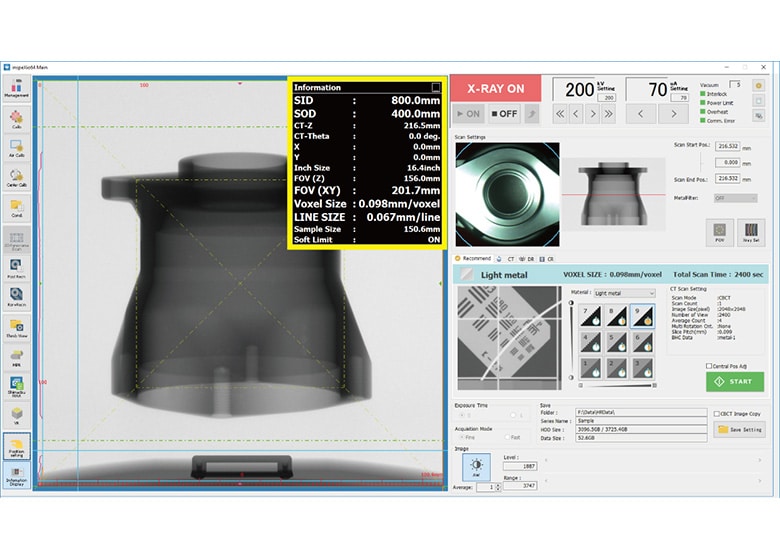

In addition to the automated CT scanning function, which relieves the operator from having to specify parameter settings, the system also includes an improved version of the HPCinspeXio ver. 3.0 high-performance computing system, providing 50 times faster processing speeds.

-

News / Events

-

inspeXio 7000 has been released

The inspeXio 7000 is a high-performance microfocus X-ray CT system equipped with a Shimadzu microfocus X-ray generator and a large high-resolution flat panel detector.

-

New Video: Package Mixup

A package mixup unfolds between two passersby. The two take an unexpected approach to solve the issue.

-

Using the experience from analyzing such a wide variety of materials to consider battery fields

We interviewed Keiji Sumiya from the Japanese chemical manufacturer Showa Denko Materials Co., Ltd (At the time of the interview., currently, Resonac Holdings Corporation). Showa Denko Materials is a global company that offers one-stop solutions for a variety of challenges in fields ranging from advanced materials to technical services.

-

Xslicer SMX-6010 microfocus X-ray inspection system enables vertical CT imaging

Xslicer SMX-6010 microfocus X-ray inspection system enables vertical CT imaging 3D Observation to Support Failure Analysis in the Electronics Industries.

-

Cellulose nanofibers

Given that cellulose nanofibers(CNFs)offer attractive physical characteristics, such as light weight, strength, and hardness, they not only enable materials with advanced functionality, but are expected to be used as a reinforcing material that can reduce the weight of composite materials.

-

Latest issue of Shimadzu Journal, featuring Materials Science, has come out.

This issue focuses on Materials Science particularly on lithium-ion batteries (LiBs). It starts with two customer interviews in which users discuss their relationship with Shimadzu.