Evaluation of an Ultra-Compact EV Door

For the development of mobility parts, it is important to investigate the construction, composition, and innovations included in popular new products and then reference the results during the in-house development work. Benchmark evaluations using a variety of analytical and measuring instruments make it possible to obtain information about the construction and composition of parts quickly and in detail. This page describes an example of benchmarking a door used in an ultra-compact EV.

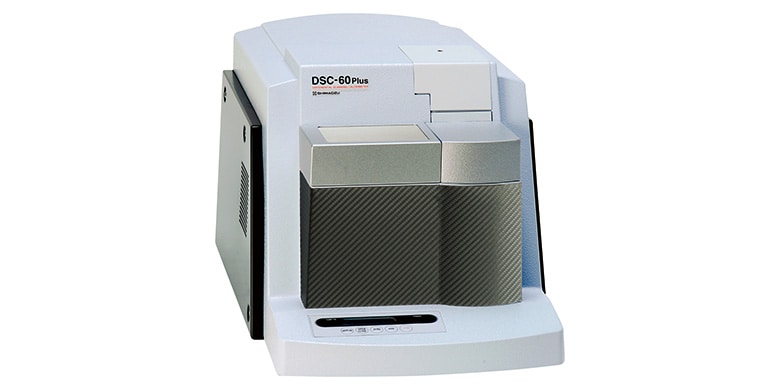

1. Observation of Internal Structures

X-rays were used to fluoroscopically observe the internal structures in the door. Because the door is large, it was cut into upper and lower sections and then several fluoroscopic images were acquired. These images were combined to visualize the overall door. The images show a high ratio of plastic material used as well as a few metal parts. Though difficult to see externally, the images show the construction of the metal parts and the status of adhesive applied to join the inner and outer plastic materials together.

Related Products

2. Evaluation of Mechanical Properties

-

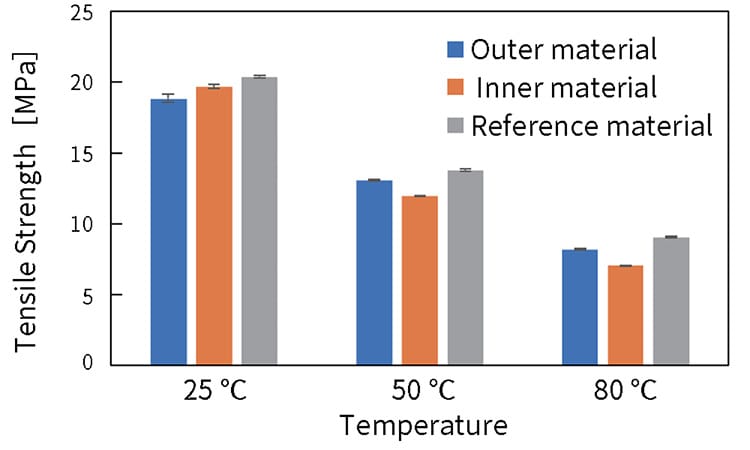

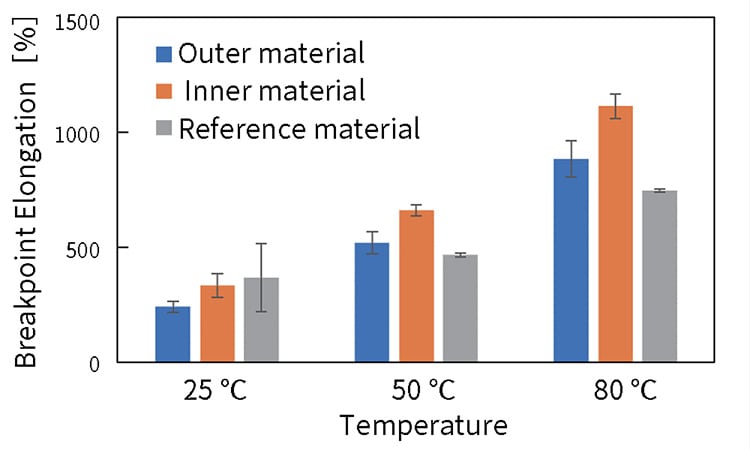

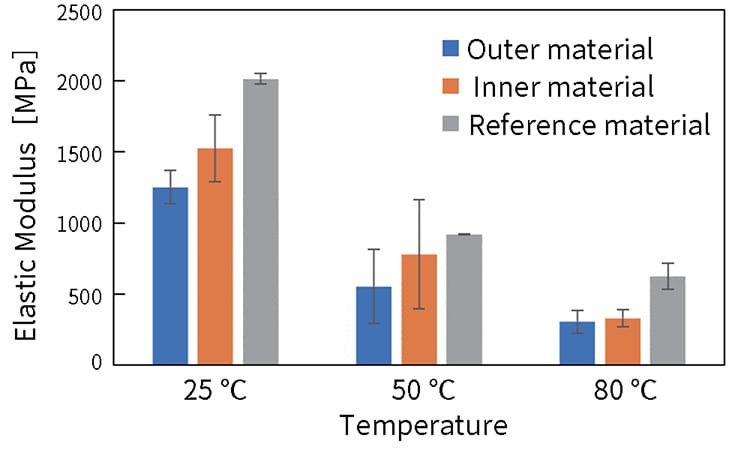

A precision universal testing machine was used to evaluate the mechanical properties of the outer material, inner material, and a reference material and evaluate their temperature dependence. The tensile strength, breakpoint elongation, and elastic modulus of three types of samples were measured at each of three measurement temperatures—25, 50, and 80 °C.

The tensile strength of all the samples tended to decrease more at higher temperatures, but there was little difference observed between the sample types.

The breakpoint elongation of all the samples increased with higher temperatures, with the outer and inner materials showing much higher temperature dependence than the reference material.

In contrast, the elastic modulus of all the samples decreased as the temperature increased, with lower values for the outer and inner materials than for the reference material, within the same temperature zone. -

Sample Shape Conforms to JIS K 7139 type CP small tensile testing samples Sample Type Ultra-compact EV: Outer and inner materials

Japan HEV: Reference materialTest Type Tensile test Test Speed 1 mm/min and 50 mm/min (switchover at 0.3 % displacement) Temperature 25, 50, and 80 °C Number of Tests 3

Evaluation of Tensile Strength Temperature Dependence

Evaluation of Breakpoint Elongation Temperature Dependence

Evaluation of Elastic Modulus Temperature Dependence

Related Products

3. Analysis of Organic Components

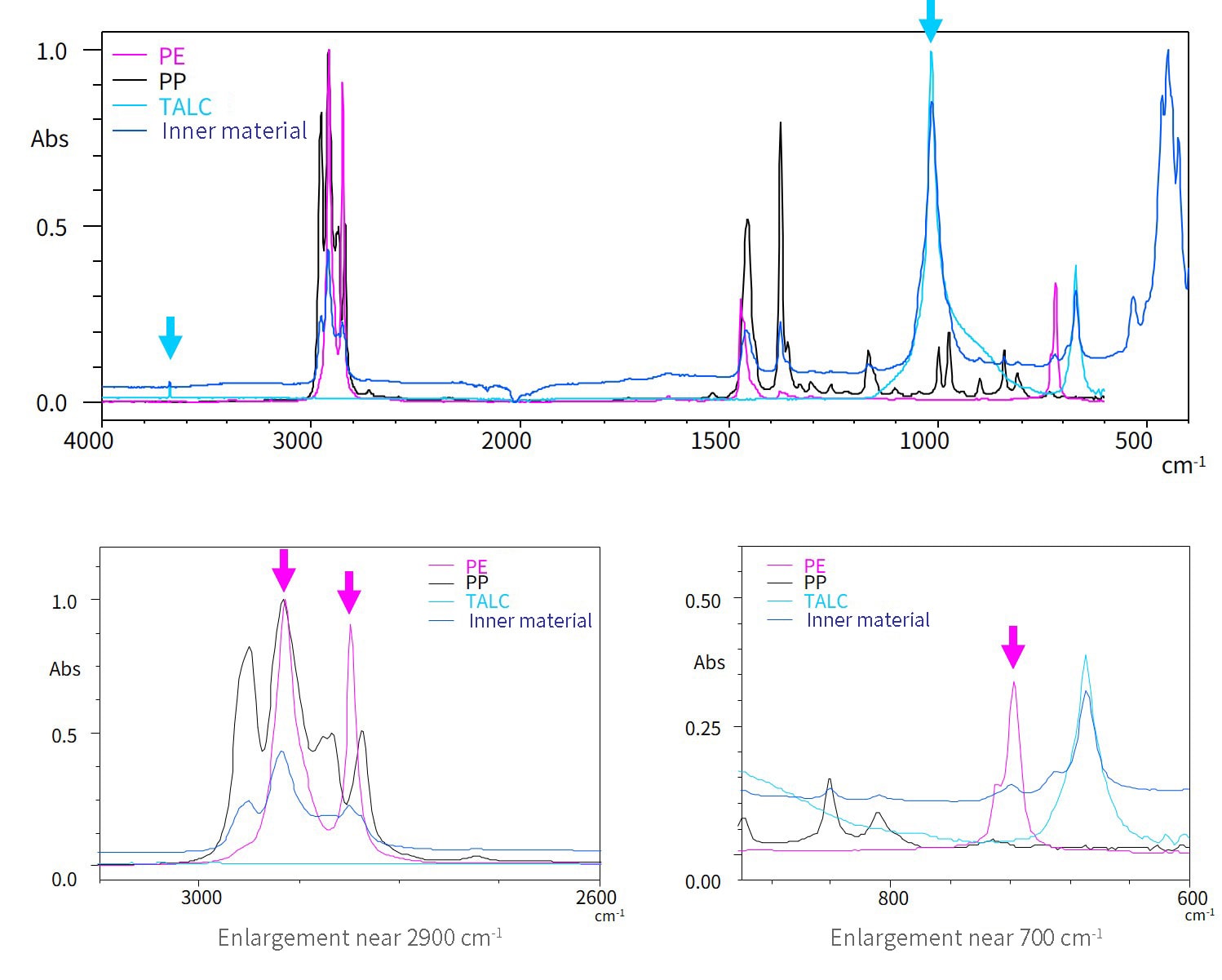

Infrared Spectra

Samples were analyzed using a Fourier transform infrared spectrophotometer to determine the presence of any organic components. Analysis was performed using the single reflection ATR method. A database search for spectra that matched the spectra obtained confirmed that the organic component was polypropylene. In terms of non-organic ingredients, a large peak for the inorganic additive talc was confirmed. In addition, a small peak appeared at the wavenumber that indicates polyethylene. These results indicate that all three materials are the same and no significant differences were apparent between the spectra.

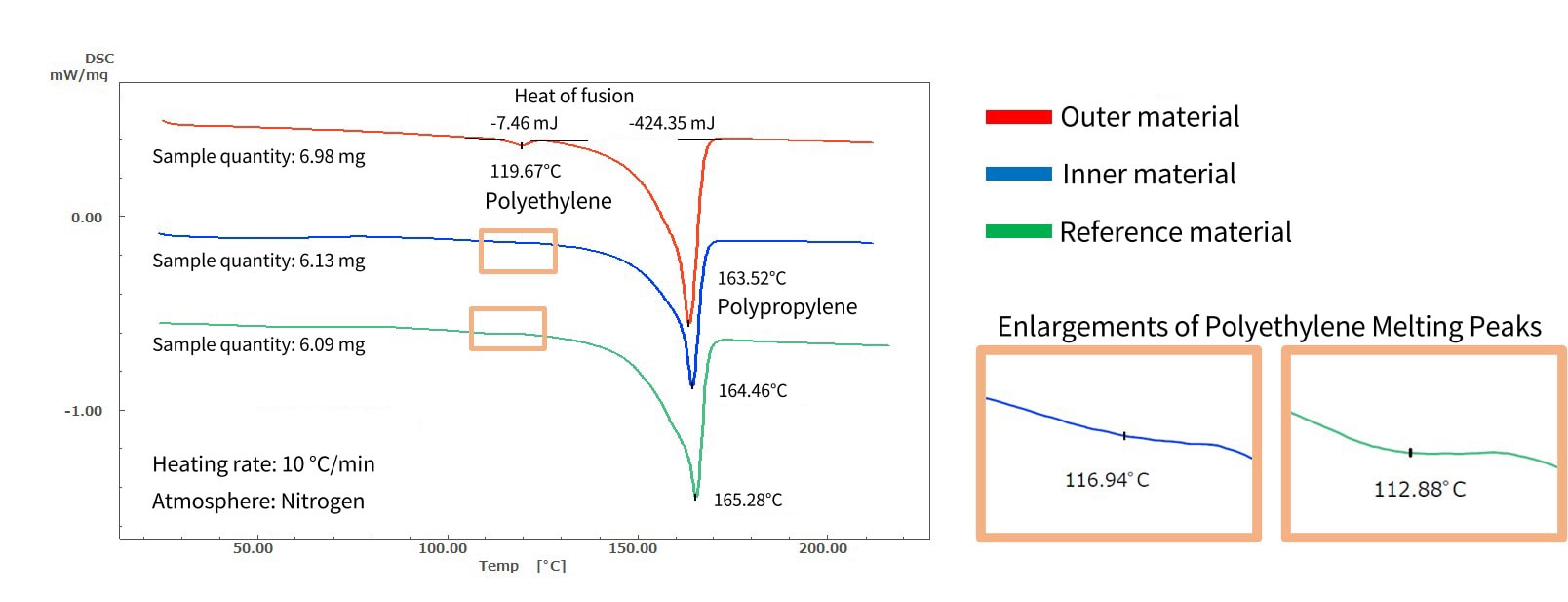

DSC Curves

The same samples were also analyzed in a differential scanning calorimeter. Results showed a large peak that indicates melting of polypropylene near 160 °C and a small peak that indicates melting of polyethylene near 120 °C. Just as with infrared spectroscopy, the graphs suggest that all three materials contain polypropylene and polyethylene.

Related Products

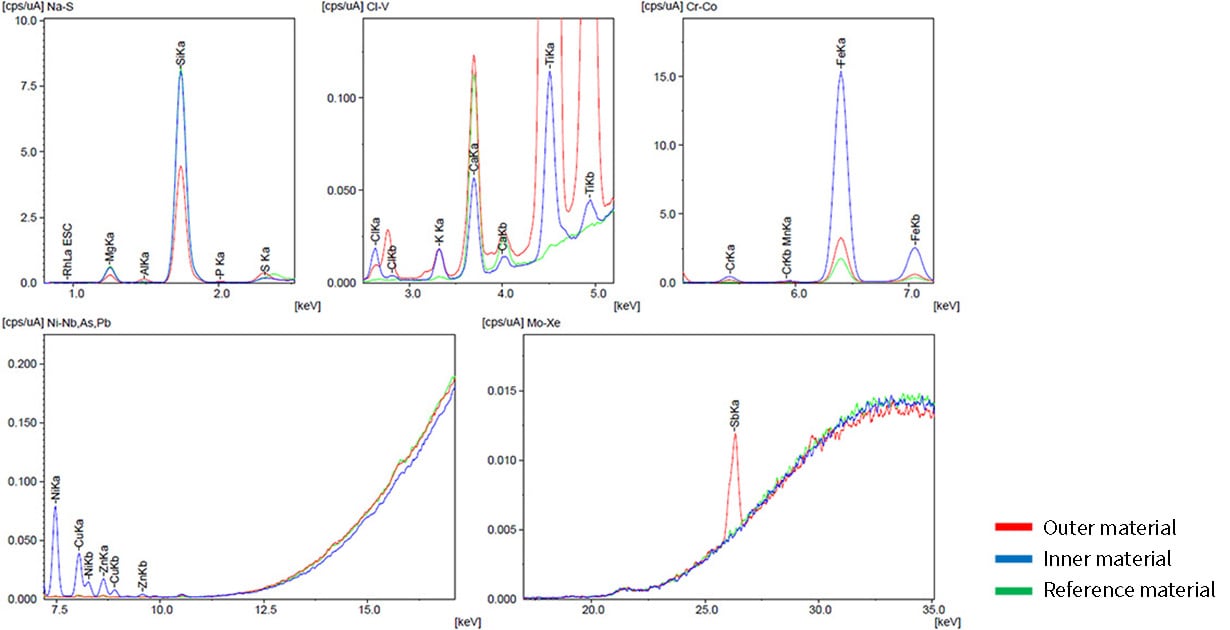

4. Inorganic Component Analysis

X-Ray Fluorescence Spectra

Samples were analyzed using an X-ray fluorescence spectrometer to determine the presence of any inorganic components. Infrared spectroscopy and thermal analysis detected both talc and iron in all three materials. Though there were some differences in the content of other components depending on the material, the results confirmed that the samples contained nickel, copper, zinc, antimony, titanium, aluminum, and other components. Though details about the specific purpose of each component are unclear, antimony is an additive used to provide flame resistance and titanium, copper, aluminum, and other elements might have been added as colorants.

Related Products

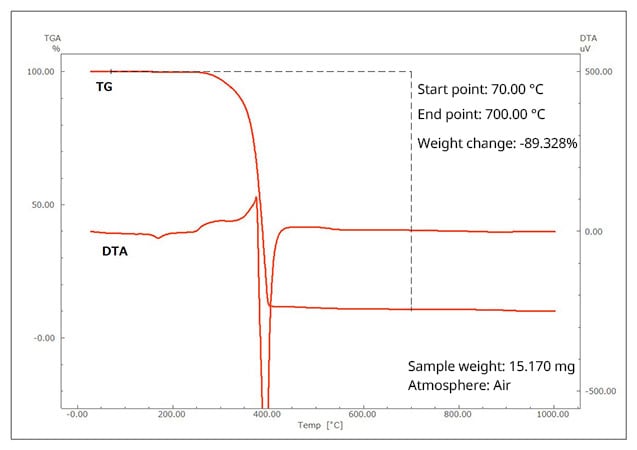

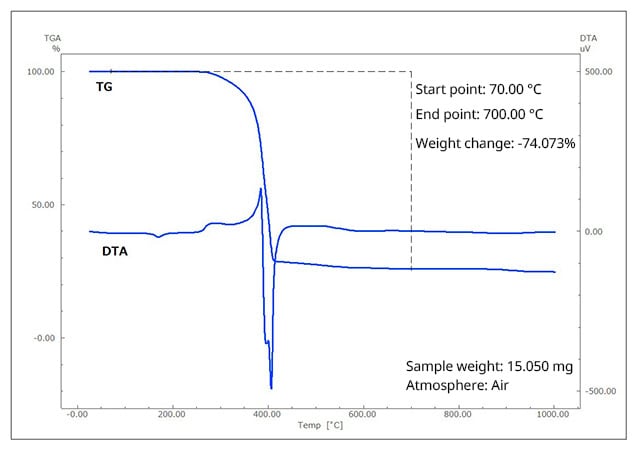

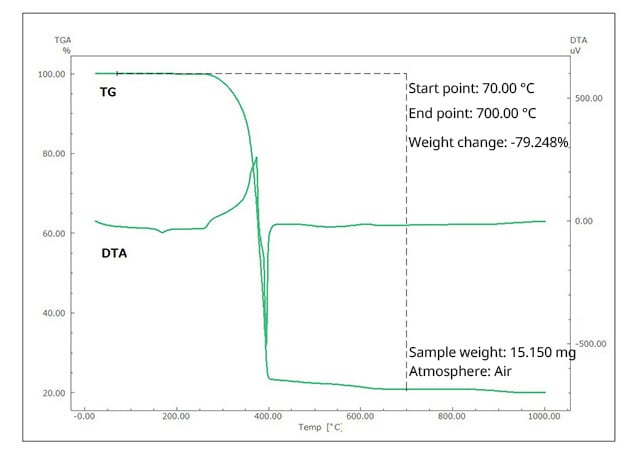

5. Calculating the Polymer/Filler Ratio

Thermogravimetric measurements were performed to calculate the ratio of polymer and filler components in each material. Each graph was plotted with temperature plotted on the horizontal axis, thermogravimetric change (TG) on the left vertical axis, and differential heat (DTA) on the right vertical axis. The graphs show that the materials have different polymer/filler ratios, with the greatest difference between the outer and inner materials.

Outer material

Inner material

Reference material

Heating rate: 20 °C/min, Atmosphere: Air

| Outer material | Inner material | Reference material | |

|---|---|---|---|

| Polymer | 89.33 | 74.07 | 79.24 |

| Filler | 10.67 | 25.93 | 20.76 |

Polymer/Filler Ratio

Related Products

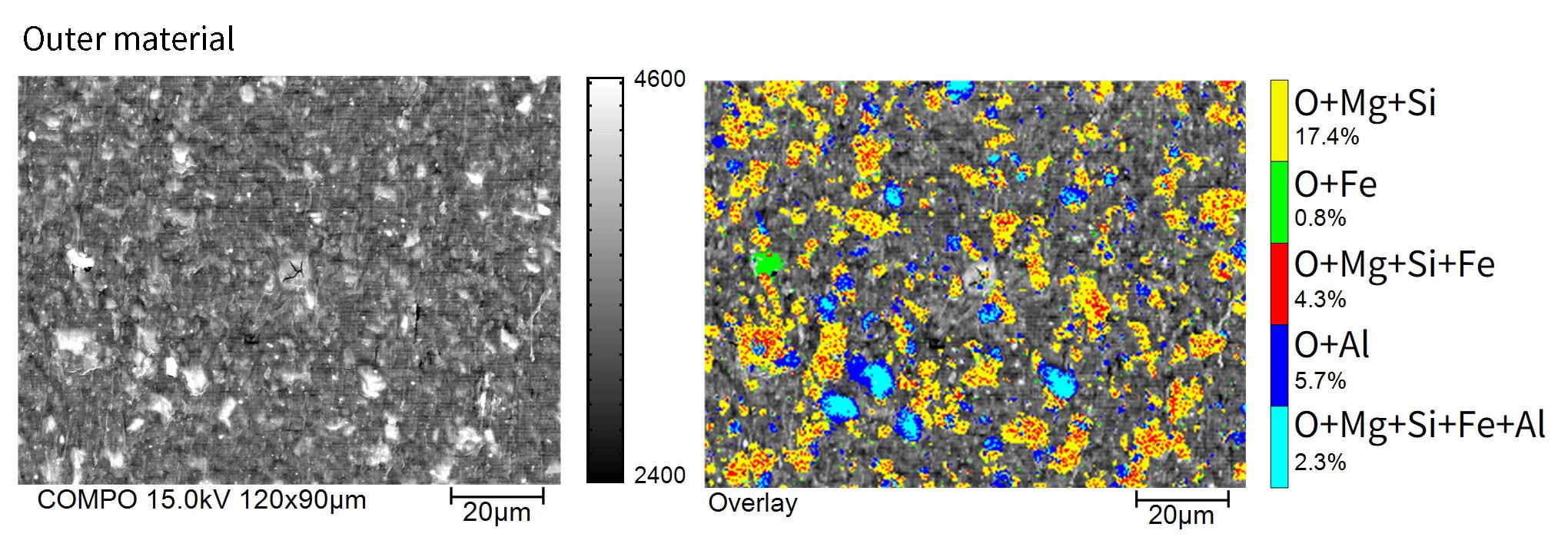

6. Element Mapping Analysis

To investigate the distribution of components in the samples, an electron probe microanalyzer was used to map the elements. Reflection electron composition images are shown on the left; these were overlaid with multiple element mapping analysis results, shown on the right. The yellow areas indicate locations with talc and the red areas indicate locations that contain talc and iron. A comparison of the outer and inner materials shows that the talc particles in the inner material tend to be larger than the particles in the outer material.

It is generally known that larger particles of talc equate to lower costs. Therefore, different materials might have been selected for different locations for cost-cutting purposes.