Chemical Substances Management

Shimadzu uses a wide variety of chemical substances for manufacturing, R&D, application development, and other activities. Handling these improperly could cause an incident or accident and many are governed by a variety of laws and regulations.

Therefore, through cooperation between the departments in charge of legal and regulatory compliance and the departments using the chemical substances, Shimadzu makes sure the substances are managed appropriately in accordance with applicable laws and regulations. In addition, Shimadzu also ensures chemical substances are managed appropriately from a business continuity planning (BCP) perspective, such as by confirming that each department has applicable import/export licenses, conducts emergency response training for each item, and is making progress replacing hazardous substances with safer alternatives.

Also, the Chemical Registration Information System (CRIS) developed by Shimadzu System Development Corporation is used to control individual chemical agents entering and leaving the company. In addition to managing the quantities of chemical substances when they are purchased, used, and discarded, this system can also be used to calculate total inventory and usage quantities and quickly issue governmental reports required by PRTR (pollutant release and transfer register) laws.

Usage of PRTR-Reported Substances in Japan

Development of CRIS Chemical Management System

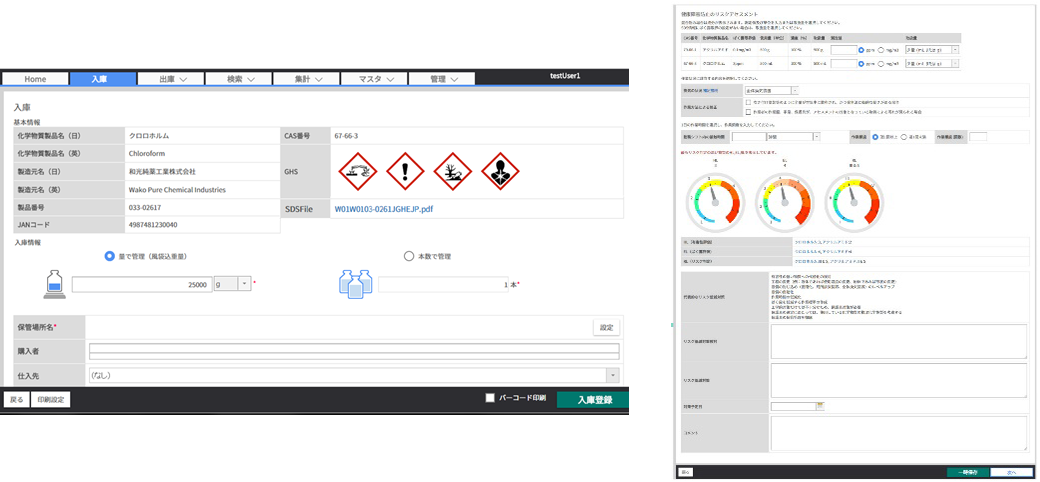

CRIS (Chemical Registration Information System) was developed in 2001 by Shimadzu Trustech Co., Ltd. (Shimadzu System Development at that time) in cooperation with the Faculty of Engineering, Kyoto University. To date, it has been adopted by more than 160 universities, research institutes and companies, including Kyoto University and Waseda University. CRIS offers a variety of optional software that is customized and upgraded to meet your needs (a screen example of risk assessment option on the right).

The left is an example of a CRIS inventory registration screen. GHS hazard marks (GHS: Globally Harmonized System of Classification and Labelling of Chemicals) and Safety Data Sheets (SDS) can be easily displayed at the time of drug registration.

Example of CRIS Screen, Chemical Management

Reduction of Chemical Substances in Manufacturing Processes

In fiscal 2016, Shimadzu completely eliminated the use of hydrochlorofluorocarbons (HCFCs), an ozone-depleting substance, in the cleaning process during manufacturing.

Hydrofluorocarbons (HFCs), which have become widespread as substitutes for HCFCs, do not destroy the ozone layer; however, they are one of the factors that promote global warming, and regulations are advancing. Our company uses HFCs in some cleaning agents, but we are working towards phasing them out completely by the fiscal year 2028.