Recycling Resources

Promoting Proper Waste Disposal and Recycling

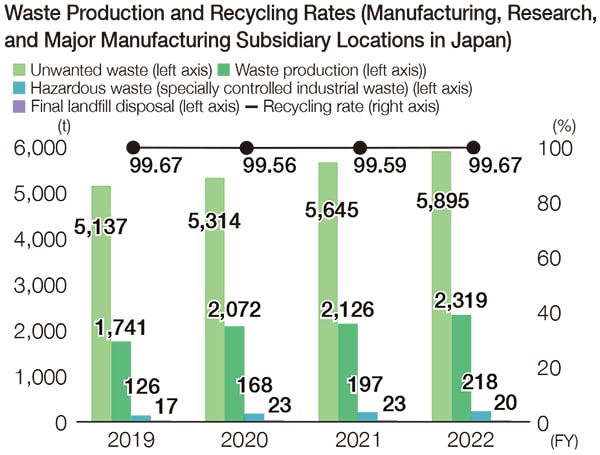

In FY2024, the total amount of waste generated from major domestic sites and research institutes was 5,742 tons, a 3.9% increase from the previous year. Of this, general waste amounted to 2,313 tons, representing a 5.0% year-on-year increase. This was due to an increase in waste liquid resulting from partial process changes. Under the Plastic Resource Circulation Act, the amount of industrial plastic waste from plastic‑used products was 492.5 tons, an increase from the previous year’s 482.9 tons. This represents 102.0% compared to the previous year, and we were unable to achieve the target of keeping emissions below the previous year’s level. However, we have been advancing initiatives such as the material recycling of plastic packaging materials.We have set a target of maintaining a recycling rate of 99% or higher, defined as (total waste - final landfill disposal) ÷ total waste. In FY2024, we achieved a recycling rate of 99.62%, marking the 15th consecutive year of meeting the target. Additionally, the waste-to-sales intensity was 1.1 tons per 100 million yen in FY2024, achieving our target of 1.2 tons or less.

Our group is committed to the efficient use of the Earth’s limited resources and to the establishment of a circular society. At each workplace, we appoint Eco and Industrial Waste Leaders who promote compliance with laws and regulations as well as the 3Rs (Reduce, Reuse, Recycle).As an example, in February 2024, we introduced “PaperLab,” an in-office dry papermaking system that operates without using water. It is used to recycle confidential documents into 100% recycled paper, which is then repurposed for employee business cards and promotional materials. In addition, we have established internal rules and procedures to promote waste separation and recycling, manage manifests, and conduct on-site audits of waste disposal contractors.

Initiatives for a Circular Economy

A variety of business models are being explored to shift from a linear economy, based on mass production, mass consumption, and mass disposal, to a circular economy that extends the value of products and resources and minimizes the amount of waste generated.

Initiatives to Extend Product Life

We are promoting the refurbishment of testing machines as part of our efforts to extend product life. By reusing the frames of existing testing machines and upgrading them with the latest controllers, this approach enhances functionality while contributing significantly to resource circulation and reducing environmental impact across the entire product life cycle.

Going forward, we will expand this refurbishment business to products beyond testing machines. By developing long-lasting products and reducing environmental impact through component replacement, we aim to advance a more sustainable business model.

Using Sustainable Materials to Reduce Environmental Impact

To support the transition to a circular economy, we are promoting the adoption of sustainable materials in new products and the replacement of materials in existing products and components, through the cross-departmental Sustainable Materials Promotion Committee, which aims to enhance our value as a company committed to solving environmental challenges. The Committee is advancing the use of biomass and recycled materials, and driving efforts to accelerate the shift toward a circular economy.

In FY2024, we adopted a biomass-based plastic for the inlet protection cap of our turbo molecular pumps, and successfully used recycled PC/ABS and other materials in the exterior components of the latest UV-Vis spectrophotometer, the UV-1900i Plus. In the future as well, we will continue achieving the transition to a circular economy specified in the medium-term management plan by reducing the amount of petroleum-based plastics used and the quantity of CO₂ emitted.

Inlet and Outlet Protection Cap for

Turbomolecular Pump

UV-Vis Spectrophotometer

UV-1900i Plus

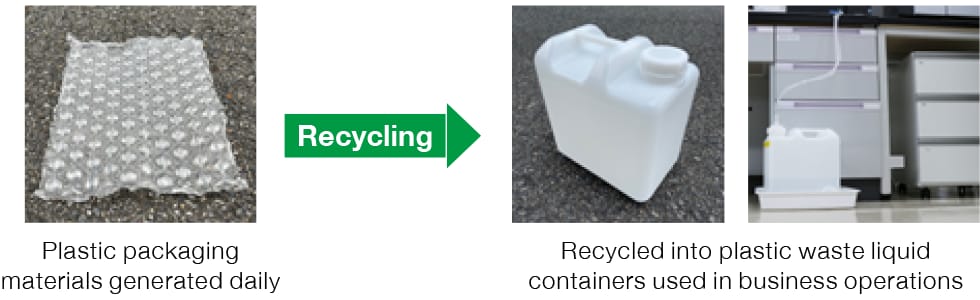

Reducing Environmental Impact through Closed-Loop Recycling

Since FY2022, to reduce the use of polyethylene, a type of plastic, we have been converting used packaging materials into pellets and mixing them with virgin pellets to produce polyethylene containers with a 30% recycled content, which are used as waste liquid collection containers at our plant at the Head Office. Ryukoku University has also joined this resource circulation initiative since FY2023. We signed a comprehensive partnership agreement with the University to promote a recycling-oriented society, and are working together on the transition to a circular economy through activities such as co-hosting seminars.

In the foreground is a polyethylene container

made of 30% recycled pellets

The Handling of PCBs

Transformers, capacitors, and other devices containing highly toxic PCBs (polychlorinated biphenyls) are disposed of in accordance with the Japanese Act on Special Measures Concerning Promotion of Proper Treatment of PCB Wastes. (PCBs are particularly toxic to biological organisms because they are highly persistent and bioaccumulative.) Of the PCB waste materials owned by Shimadzu, Shimadzu started processing transformers and capacitors, which contain high PCB concentrations, in FY 2013 and will finish processing all the PCB waste within the time frame specified in the Japanese Act on Special Measures Concerning Promotion of Proper Treatment of PCB Wastes.

Meanwhile, Shimadzu Techno-Research Inc., a Shimadzu Group company, offers an easy method for analyzing the quantity of trace PCBs in two types of insulating oil. This measurement technology is able to quickly and inexpensively provide highly reliable measurement values and was even included in the Manual for Simplified Measurement of Trace PCBs in Insulating Oil (3rd edition), published by the Japanese Ministry of the Environment in May 2011.

Promoting Environmentally-Friendly Packaging

Shimadzu Logistics Service Corporation is engaged in a wide variety of activities for environmental conservation within its logistics activities. Of these, they are currently focused on switching to more environmentally-friendly packaging materials. Previously, heavy items were typically packed in crates made of lumber and plywood, but now they are switching to reinforced corrugated cardboard. The environmental benefits of switching to reinforced corrugated cardboard include conserving wood resources and reducing CO2 emissions during transport or incineration of the packaging materials. If wood materials are used, materials from Forest Stewardship Council-certified forests are recommended as a measure to promote biodiversity.

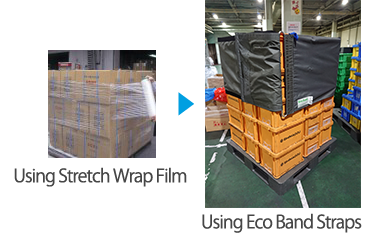

Furthermore, in an effort to reduce the amount of stretch wrap film (plastic) used to prevent loads from falling during transit, they started using reusable and efficient Eco Band pallet straps. Using the Eco Band straps has reduced the amount of plastic waste by 460 kg in FY2020.

We intend to continue activities in the logistics field that help conserve the environment.

At a Shimadzu Group company in the UK, employees have been actively involved in implementing environmentally-friendly reusing practices. One such measure is the “reusable supplier delivery container project,” which involves using reusable packing boxes to transport purchased parts or service parts from suppliers. The container was designed in cooperation with suppliers based on operations during production. Using the containers, which are designed specifically for packing the given parts, offers a wide range of benefits, such as reducing expenses from damage during transit and from less disposable corrugated fiberboard box waste.

Independently Designed Supplier Delivery Containers