Pollution Measures

Air Quality Measurements (Sanjo Works)

SOx and NOx levels in exhaust gases emitted from boilers used in factories are monitored regularly with respect to Shimadzu standards, which are stricter than the standards in Japanese air pollution laws and Kyoto prefectural environmental regulations.

At the Sanjo Works, aging fuel oil-fired boilers and natural gas boilers are being replaced successively to help prevent air pollution and to reduce CO2 emissions. In FY 2014, all of the fuel oil-fired boilers have been replaced.

Water Quality Measurements

Plant effluents are regularly measured with respect to Shimadzu standards, which are stricter than the standards in Japanese wastewater laws and Kyoto city wastewater regulations. In addition to regular measurements of each water quality parameter, the Sanjo Works also utilizes a specialized monitor and intranet LAN to continuously monitor pH and TOC (total organic carbon) levels. Also, a rapid response system has been built to send email notification to the person in charge of the problem if the pH level of wastewater exceeds the Shimadzu standards.

In addition, the total organic carbon (TOC) in wastewater is constantly monitored at its main production sites, Sanjyo, Seta and Hadano Works, and its research and development sites, Technology Research Laboratory (Keihanna) and Shimadzu Tokyo Innovation Plaza. TOC is the total amount of carbon that constitutes organic matter in water and is one of the leading indicators of water quality. TOC Analyzer is ideal for upstream wastewater monitoring applications because it can detect organic pollutants very quickly. By disseminating many examples of its use in our company to the public, we hope to promote its use in the real world, and to support our customers' environmental efforts.

On-Line Total Organic Carbon Analyzer

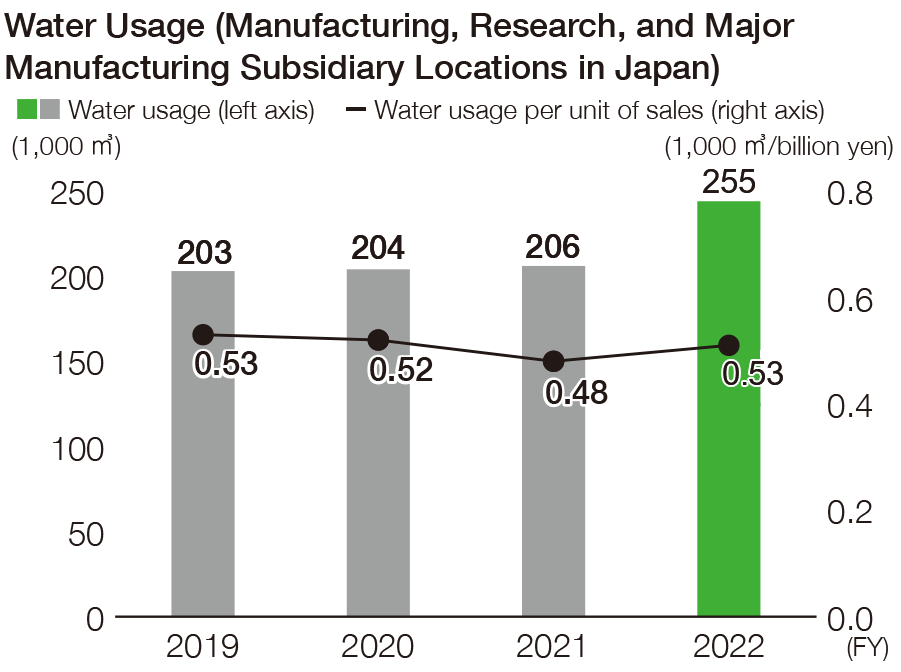

Water Management

We are committed to reducing water usage by utilizing rainwater for watering green areas and by adopting water-saving fixtures. In FY2024, total water consumption by the Shimadzu Group in Japan and overseas was 340,000 m³, a 1.5% increase compared to the previous year. However, water consumption per unit of net sales improved to 63.0 m³ per 100 million yen, a 3.6% year-on-year improvement. Our medium-term goal is to reduce water consumption per unit of consolidated net sales by 5% by FY2030 compared to FY2020 levels. As of FY2024, we have achieved a 0.8% improvement toward this target.

Factory effluents are controlled to voluntary standards that are stricter than required by laws or regulations. At major manufacturing and research facilities in Japan, effluent water is monitored using a real-time wastewater monitoring system built with online water quality analyzers (TOC-4200) and operated via the cloud. We will continue to implement initiatives that contribute to the sustainable use of resources.

Report on Effluent Violation

There were no violations related to wastewater in either FY2024 or FY2023.

In FY2022, Shimadzu Corporation’s Seta Works (Otsu City, Shiga Prefecture) was notified by Otsu City that effluent discharged from the site contained a concentration of n-hexane extract (42 mg/L) exceeding the regulatory limit specified in the Sewerage Act (30 mg/L or less).

An investigation identified the source as wastewater discharged from the kitchen. In response, (1) a request was made to the kitchen contractor to take thorough measures to prevent contamination with oil, etc., and (2) measures were taken to clean the pipes in the kitchen systems. These actions were reported to Otsu City. Continued follow-up monitoring confirmed the effectiveness of the measures, and a monthly cleaning

schedule for the kitchen was established and is now in place, resolving the issue.

Third Party Assurance of Environmental Data

Shimadzu Corporation received a third-party assurance from Deloitte Tohmatsu Sustainability Co., Ltd., to disclose highly reliable environmental impact data.

[Assurance coverage]

Period covered: April 1, 2023- March 31, 2024

Scope of the report: Head office, works, research laboratory, branch offices, and sales offices of Shimadzu Corporation and major group companies in Japan

Extent:Tap water consumption(m3), Groundwater consumption(m3)

- *Click on the image to view the PDF.

Calculation Report Tap water consumption