In recent years, there has been particular interest in ensuring the safety of food and the early diagnosis of human illnesses, which requires identifying the presence and quantities of harmful substances in food and the body. However, food and blood can contain a wide variety of the components that must be analyzed using a variety of techniques and instruments. Consequently, obtaining more accurate analytical results more quickly remains a major issue.

Recently, in a joint research program with a research institution, Shimadzu developed a revolutionary new product that can solve these issues and that is especially environmental friendly.

Nexera UC Supercritical Fluid Extraction/Chromatograph System

Residual pesticides contained in foods are an extremely important problem, not only for consumers that actually eat the foods, but also for the producers and suppliers of the food. Due to the diverse types of target components involved in analyzing residual pesticides, analysis requires selectively using various different instruments depending on the component. For example, residual pesticides in vegetables are typically analyzed using a gas chromatograph mass spectrometer (GCMS)*1 system, which is able to separate the compounds so that they can be identified and their mass analyzed. However, GCMS systems separate components by vaporizing samples with heat, which makes it difficult to analyze components that are changed by heat or substances that are difficult to vaporize. Therefore, a separate liquid chromatograph mass spectrometer (LCMS)*2 system is also required. Additionally, samples must be prepared in a process called pretreatment before they can be analyzed. For example, vegetables must be homogenized, mixed with a reagent, and stirred, which is a time-consuming manual process. Furthermore, it can be extremely difficult to analyze the wide variety of components accurately, because some of them oxidize or decompose when exposed to air. However, these problems can be solved by using substances called supercritical fluids*3, which have the properties of both gases and liquids. This allows a wide variety of components to be analyzed simultaneously without the need for any complicated pretreatment processes. Such instruments, called supercritical fluid chromatographs (SFC), are a revolutionary new type of instrument that not only can analyze substances that are difficult to analyze using a GCMS or LCMS system, but can also analyze substances at high speed. However, only a limited number of manufacturers offer SFC systems in Japan. Due to Japan's High Pressure Gas Safety Act governing such instruments and other issues, they have been slower to gain widespread use in Japan than overseas. Consequently, development of technology for SFC pretreatment currently remains at the research level.

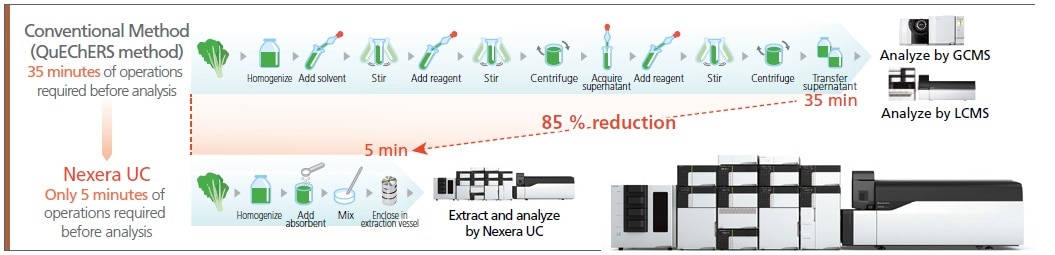

Comparison to Conventional Example of Pretreatment for Simultaneous Analysis of Residual Pesticides in Agricultural Products

Nexera UC System Developed from the Japan Science and Technology Agency (JST) Program for the Development of Systems and Technology for Advanced Measurement and Analysis

As part of the Japan Science and Technology Agency program for the Development of Systems and Technology for Advanced Measurement and Analysis, Shimadzu has been involved in joint research and development in cooperation with Osaka University, Kobe University, and the Miyazaki Agricultural Research Institute.

This resulted in announcing the development of a new Nexera UC system in January 2015. The Nexera UC is a revolutionary new analytical system that is the world's first system capable of simultaneously analyzing multiple components fully automatically and at high speed.

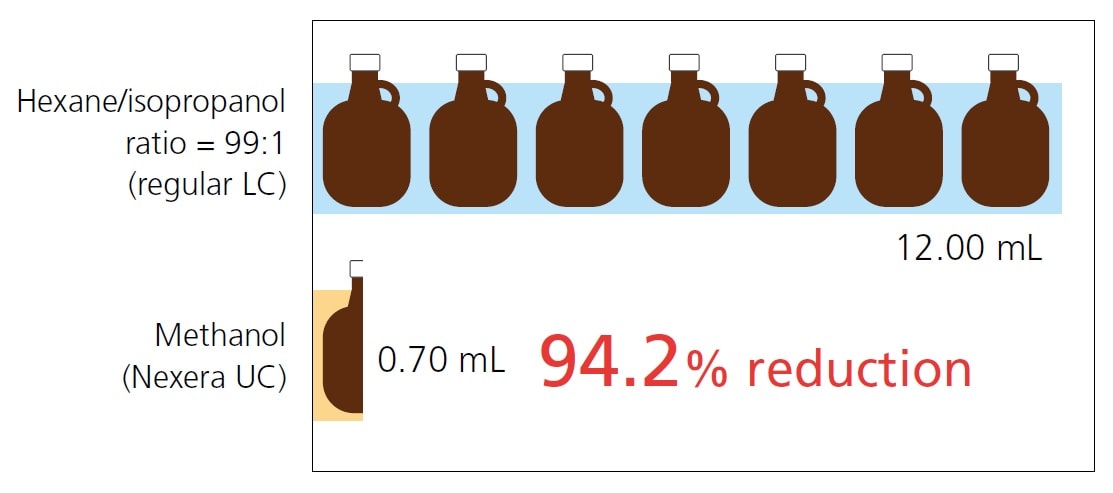

The new Nexera UC system shortens the previous 35 minute pretreatment process to about 5 minutes and has made it possible to comprehensively analyze about 500 pesticide components simultaneously in less than an hour, about half the time required previously. Meanwhile, it also reduces the quantities of organic solvents used for analysis to about one tenth the previous level. Organic solvents are primarily flammable chemical substances refined from petroleum that are also hazardous substances toxic to humans. Consequently, the system also helps reduce any environmental impacts and increase safety during analysis.

Due to the high throughput (by analyzing multiple components simultaneously) possible with the system, these extremely accurate analytical instruments are also gaining interest from medical and drug discovery fields. For example, by analyzing specified components in the blood as biomarkers, the system can be used for ultra-early diagnosis of diseases and for evaluating the efficacy or adverse effects of pharmaceuticals. The system is also expected to be beneficial in all sorts of other fields, including foods, medications, and the chemical industry, such as for analyzing the additives in plastics. Shimadzu will continue to partner with leading customers in joint research and joint development projects to develop truly unique new products and new systems that contribute to the growth of our customers around the world.

Comparison of Solvent Consumption During Analysis

- *1: Gas chromatograph mass spectrometers(GCMS)

Used to determine the presence and quantity of components in a sample mixture containing many components by heating the sample to thermally decompose it and separate its components in gaseous form. - *2: Liquid chromatograph mass spectrometers(LCMS)

Used to determine the presence and quantity of components in a sample mixture containing many components by separating the sample in liquid form. - *3: Supercritical fluid

Usually carbon dioxide, which can form a supercritical fluid with properties of both gases and fluids at temperatures above a critical temperature of 31.1 ℃ and critical pressure of 7.38 MPa

Comments from a Joint Researcher Partner

We have been researching SFC because it is an analytical technique capable of high separation at high speed and high throughput, it offers separation modes not available from liquid chromatographs, and because it is attractive as an analytical technology with hidden undeveloped potential.

The goal of the joint development program, to not only connect a mass spectrometer, but also a supercritical fluid extraction unit online, had a rather high level of difficulty. However, by working closely with experts from respective fields, gathered from the organizations involved in the project, who shared a common desire to introduce an unprecedented new system to the world, we were able to successfully create a fantastic system that combines the ideas and dreams of all participants.

Due to the shorter analysis times and lower organic solvent consumption rates, the new system is able to significantly reduce costs and environmental impacts. Therefore, we anticipate that it will be especially beneficial as a new technique for high throughput analysis in applications such as clinical testing and food safety inspections.

Professor Takeshi Bamba

Research Center for Transomics

Medicine, Medical Institute of

Bioregulation, Kyushu University

(Formerly the JST Project Team Leader in the Division of Advanced Science and Biotechnology, Graduate School of Engineering, at Osaka University)